Established in 2021 by visionary founders Kanav Arora, Sizer Lakhani, and Rajiv Arora, Credence Ecofiber has rapidly emerged as a pioneering force in India’s PET recycling landscape. With a strong commitment to innovation, environmental stewardship, and circular economy principles, the company has positioned itself as a reliable partner for industries seeking high-quality sustainable fiber solutions. Since inception, its mission has been clear: Transform. Innovate. Sustain.

At the core of Credence Ecofiber’s operations is a state-of-the-art manufacturing facility capable of producing an impressive 120 tons of recycled polyester staple fibre (RPSF) per day, using discarded PET bottles as the primary raw material. This scale not only reflects industrial capability but also represents a meaningful contribution to reducing plastic waste, conserving resources, and minimizing the environmental burden of synthetic materials. Each bottle diverted from landfills or oceans forms part of the company’s larger narrative—one in which waste becomes opportunity and sustainability becomes measurable progress.

Transforming PET Waste into Sustainable Fiber

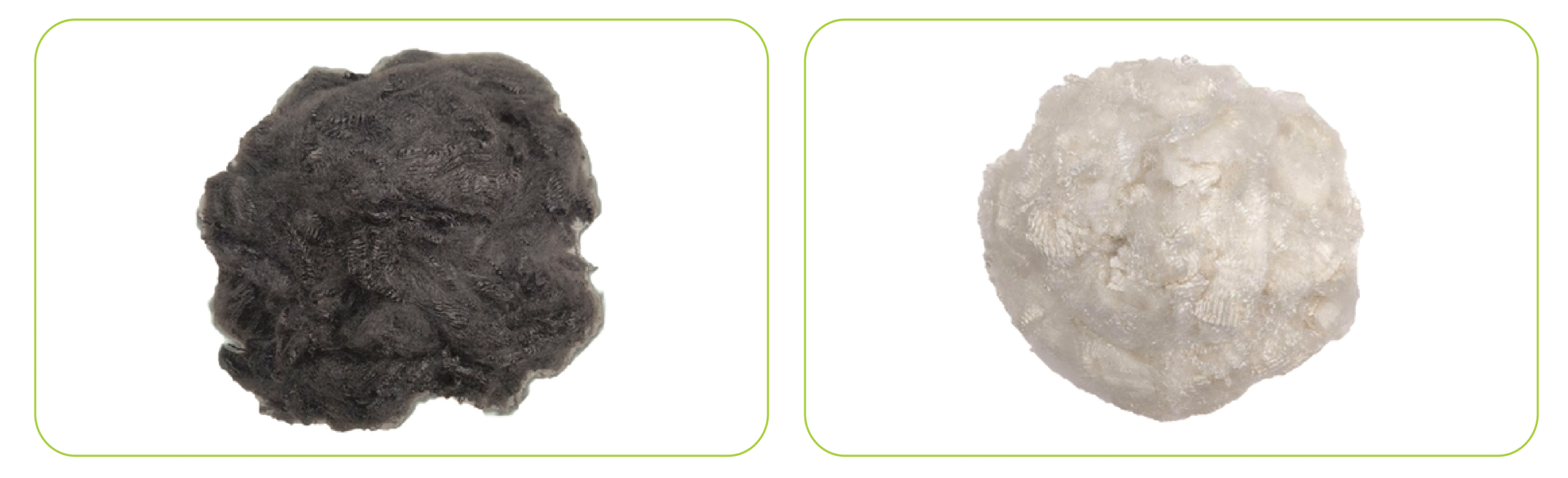

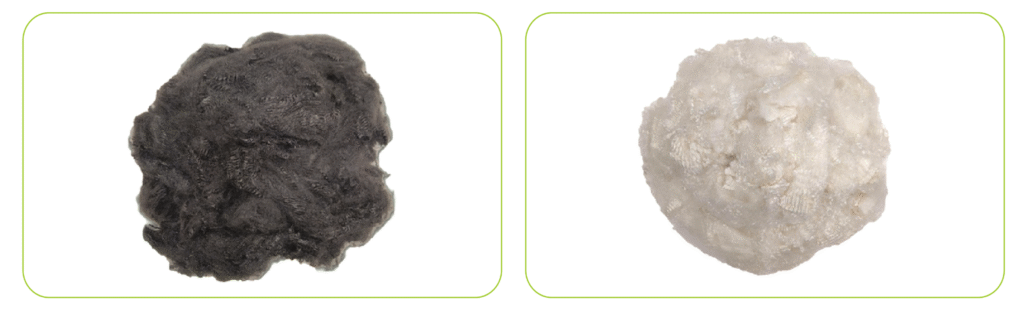

Recycled Polyester Staple Fibre has emerged as one of the most efficient and reliable substitutes for conventional synthetic fibre. Through advanced recycling processes, Credence Ecofiber transforms post-consumer PET bottles and PET/polyester waste into high-performance fibers suitable for several industrial applications. These include nonwoven carpets, wadding, filtration media, polyfill stuffing for cushions and quilts, geotextiles, and spinning yarns. By offering fibers that meet stringent quality standards, the company ensures its products integrate seamlessly into diverse textile and non-textile value chains.

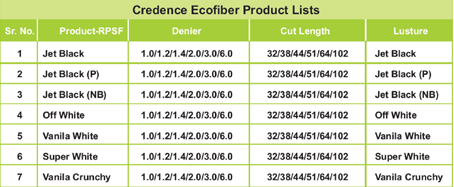

The company’s portfolio includes a wide range of RPSF variants available in multiple deniers (1.0–6.0) and cut lengths (32–102 mm), offering flexibility for various manufacturing needs. Product offerings span multiple shades and finishes, including Jet Black, Off White, Vanilla White, Super White, and Vanilla Crunchy, catering to industry-specific requirements in aesthetics, strength, and performance.

Innovation Rooted in Sustainability

Credence Ecofiber’s growth is anchored in an unwavering commitment to sustainability. Plastic waste continues to pose a global challenge, with billions of bottles discarded annually. By recovering and processing PET bottles, the company contributes to reducing landfill accumulation and limiting the need for virgin petroleum-based fibres. This shift not only reduces carbon emissions but also supports responsible resource utilisation.

Recycling PET bottles is more than just waste conversion—it is a conscious step toward environmental resilience. Each bottle recycled conserves natural resources, minimizes energy-intensive production processes, and promotes circular manufacturing systems. Credence Ecofiber plays a crucial role in demonstrating how sustainability and commercial viability can coexist.

Sustaining a Greener Future

Driven by a future-forward vision, Credence Ecofiber continues to invest in technological advancement, process efficiency, and environmental responsibility. The company firmly believes that sustainability is not a trend but an obligation—one that requires continuous innovation, ethical operations, and long-term commitment.

As global industries increasingly opt for greener alternatives, RPSF stands out as a material of the future. Through its high-capacity operations and strong quality focus, Credence Ecofiber is not only meeting market demand but shaping a more responsible manufacturing ecosystem.

In just a few years, the company has established itself as a trusted name in the recycled fiber industry—a testament to its leadership, its commitment, and its unwavering dedication to building a cleaner, greener planet for generations to come.